In today’s high-risk industrial environments, early detection isn’t just smart — it’s essential. Thermal imaging is one of the most powerful tools available to stop fires before they start. By allowing you to see heat before fire, thermal imaging provides a proactive way to protect people, property, and operations. And when paired with Fire Rover systems, this technology becomes a frontline defense — combining advanced sensors, AI, and human verification for unmatched speed and accuracy.

Whether you manage waste and recycling facilities, battery storage sites, or warehouses, understanding how thermal imaging works is the first step toward building a stronger fire prevention strategy. Let’s explore the technology, the types of systems available, and how Fire Rover uses them to safeguard facilities across industries.

What Is Thermal Imaging?

Thermal imaging allows us to visualize heat patterns rather than relying on visible light. Unlike standard cameras, which capture reflected light, thermal cameras detect infrared radiation emitted naturally by objects, people, or materials. This makes it possible to identify risks that would otherwise go unnoticed.

Thermal cameras convert heat into a visual image, known as a thermogram. Warm areas are often represented in bright colors, including red, orange, or yellow, while cooler areas appear blue or purple. This color-coded mapping highlights temperature differences, helping operators quickly identify hotspots, overheating equipment, or developing fire risks.

By detecting heat instead of smoke or flames, thermal imaging provides a valuable early-warning system — giving facilities time to respond before a small issue turns into a full-scale emergency.

How Thermal Imaging Works

At the heart of every thermal system are three key components:

- Infrared sensors that detect the heat emitted by objects.

- Image processors that convert infrared signals into a digital format.

- Display mapping that translates the data into thermograms for real-time monitoring.

The process is straightforward. Infrared radiation is captured by the sensor, transformed into electronic signals by the processor, and displayed as a color-coded image for operators to interpret.

Several factors can affect accuracy:

- Distance: Objects far from the camera may produce less detailed readings.

- Environmental conditions: Tain, fog, dust, or smoke can scatter infrared signals.

- Reflective surfaces: Glass or polished metal may distort apparent heat levels.

Even with these considerations, thermal imaging remains one of the most reliable ways to detect abnormal heat in industrial settings. Early detection systems like those used by Fire Rover enhance accuracy further by combining thermal sensors with flame detection, AI analytics, and human verification.

Types of Thermal Cameras

Choosing the right camera depends on your environment and monitoring needs.

- Handheld Cameras: Portable and versatile, ideal for inspections and troubleshooting on the move. Operator skill affects coverage and accuracy.

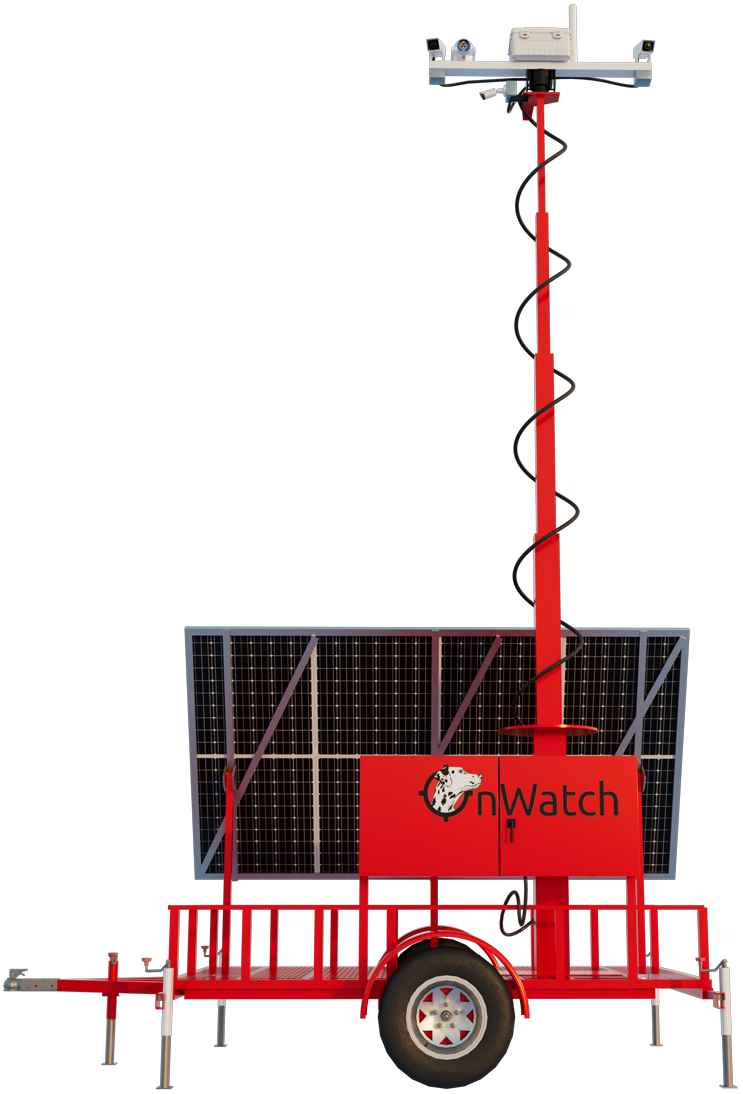

- Mounted/Fixed Cameras: Provide continuous monitoring in high-risk zones like warehouses or waste facilities. Require installation but offer constant vigilance.

- Drone-Mounted Cameras: Extend coverage to large or hazardous areas, allowing aerial inspections without putting staff at risk. Weather-dependent and require trained pilots.

- Smartphone-Attached Cameras: Low-cost, accessible, and perfect for quick scans, though limited in resolution and features.

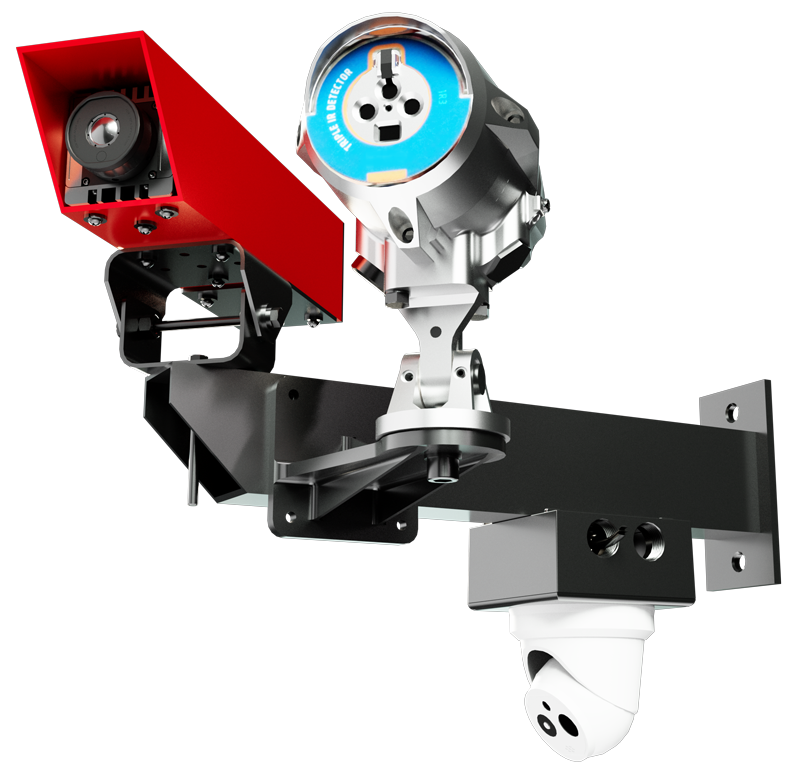

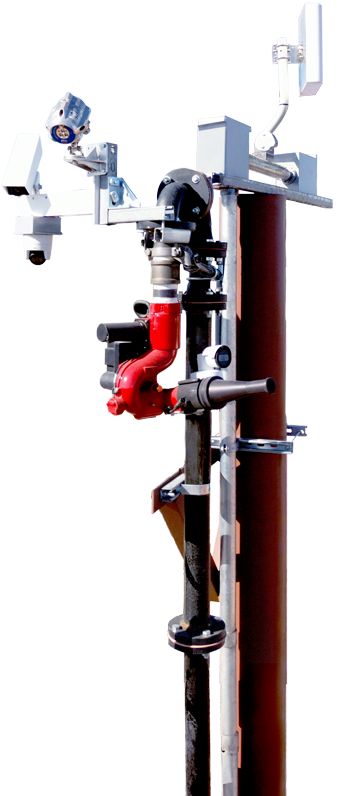

Advanced Industrial Systems (like Fire Rover): Combine high-resolution thermal sensors, AI analysis, flame and smoke detection, and live human verification. Designed for 24/7 monitoring and automated response in the highest-risk environments.

Applications of Thermal Imaging

Thermal imaging is a versatile tool across many industries.

- Fire Detection and Suppression: See hotspots before flames emerge. Fire Rover can automatically verify risks and coordinate rapid response to prevent escalation.

- Warehouses and Logistics Centers: Detect overheating machinery, electrical panels, or batteries before sparks start a fire, reducing downtime and protecting inventory.

- Waste and Recycling Facilities: Constantly shifting fire risks make monitoring critical. Thermal cameras detect hidden heat from shredded materials or smoldering piles, keeping tipping floors safe.

- Battery Storage Facilities: Early thermal detection prevents dangerous lithium-ion battery failures. Even small temperature anomalies can trigger alerts to prevent catastrophic events.

- Industrial Safety and Maintenance: Identify overheating motors, faulty wiring, or worn components before they fail, saving on repairs and downtime.

For most applications, the camera type should match the environment: handhelds for spot checks, fixed or industrial systems for continuous monitoring, and drones for mobile or hazardous areas.

The Benefits of Thermal Imaging

Thermal imaging offers clear advantages for industrial safety and fire prevention:

- Faster Detection: Hot spots are identified before smoke or flames appear, allowing early intervention.

- Increased Safety: Workers and responders are kept out of harm’s way through remote monitoring.

- Reduced False Alarms: Human verification filters out non-fire heat sources, avoiding unnecessary shutdowns or panic.

- Cost Savings: Preventing fires protects assets, reduces downtime, and minimizes clean-up costs.

When paired with advanced systems like Fire Rover, these benefits are amplified, combining early detection with automated suppression and live oversight.

Limitations of Thermal Imaging

Thermal imaging is powerful, but it’s not without challenges:

- Equipment Cost: High-quality thermal systems require significant investment.

- Operator Training: Accurate interpretation of thermograms is essential for reliability.

- Environmental Factors: Weather, dust, smoke, or reflective surfaces can affect readings.

- Myths: Thermal cameras do not “see through walls”; they measure surface heat only.

With the right system, training, and integration, these limitations can be managed effectively, ensuring reliable protection.

How to Choose the Right Thermal Imaging Solution

Selecting the best solution requires balancing capability, environment, and risk. Consider:

- Resolution: Higher resolution enables detection of smaller hot spots.

- Temperature Range: Ensure the system can handle your facility’s extremes.

- Software and Features: AI analytics, alerts, and integration with other monitoring systems improve efficiency.

- Application Fit: Handhelds for simple inspections, fixed systems for continuous monitoring, drones for mobile coverage, and full industrial solutions for high-risk operations.

The right system delivers confidence, protecting both people and property while maintaining operational continuity.

Building Safer Operations With Fire Rover

Thermal imaging is a cornerstone of modern fire safety — but when combined with Fire Rover’s AI-enhanced, human-verified, automated suppression system, it becomes a complete safety solution. From early hotspot detection to verified alerts and targeted response, Fire Rover keeps operations safe and running smoothly.

Ready to see how Fire Rover can safeguard your facility? Contact us today to learn more about our thermal imaging solutions and full fire prevention systems.