Few things spread as fast and cause as much destruction as fire. Whether in a home, workplace, or industrial facility, fire can escalate in minutes, making quick and effective suppression critical. But many people still ask: how to suppress fire safely? or what is the most common method of fire suppression?

The answer isn’t as simple as grabbing the nearest extinguisher. There are many different methods of extinguishing fire, each with advantages and limitations depending on the type of fire and the environment. In industrial settings like warehouses, recycling facilities, or manufacturing plants, choosing the wrong method can be costly — both in property damage and human safety.

In this guide, we’ll explain the science behind fire suppression, the most effective suppression methods, when systems are required by law, and how businesses can choose the right solution. By the end, you’ll understand not only how to suppress a fire but also how to do it in a way that protects people, assets, and long-term operations.

How Do You Suppress a Fire?

At its core, fire suppression is about breaking the “fire triangle”: heat, oxygen, and fuel. Eliminate one of these elements, and the fire can no longer sustain itself. Every suppression technique — from water to advanced clean agents — works by targeting at least one side of this triangle.

Traditional approaches include:

- Water: The most common method of fire suppression, cooling flames and removing heat.

- Foam: Used for flammable liquid fires, foam both cools and smothers oxygen.

- Dry Chemicals: Powder agents interrupt chemical reactions and are effective on electrical or grease fires.

- Gaseous Agents: Clean agents like FM-200 or inert gases displace oxygen, safe for electronics and sensitive equipment.

In consumer settings, suppression often means fire extinguishers, stovetop covers, or sprinkler systems. In industrial environments, however, methods must scale up: foam deluge systems, mobile suppression units, or automated systems designed for continuous monitoring and rapid response.

Common questions:

- How do you suppress a fire cheaply? Extinguishers and sprinklers are cost-effective but may not fit every risk.

- What is the most reliable solution? Automated detection with suppression systems provides the fastest response in high-risk facilities.

- What are the limitations? Water can damage electronics, gas systems are costly, and foam requires cleanup and containment.

What Is Fire Suppression?

Fire suppression goes beyond extinguishing flames — it’s a process that starts with detection, then activation, and finally suppression.

- Detection: Sensors or cameras identify heat, smoke, or flames.

- Activation: The system (manual or automatic) engages the suppression agent.

- Suppression: The agent cools, smothers, or interrupts the fire’s chemical process.

Examples include:

- Sprinklers: The most common method of fire suppression in commercial and residential buildings.

- Chemical Agents: Dry chemicals or foams used for hazardous materials.

- Clean Agent Gas Systems: Ideal for data centers and electronics because they leave no residue.

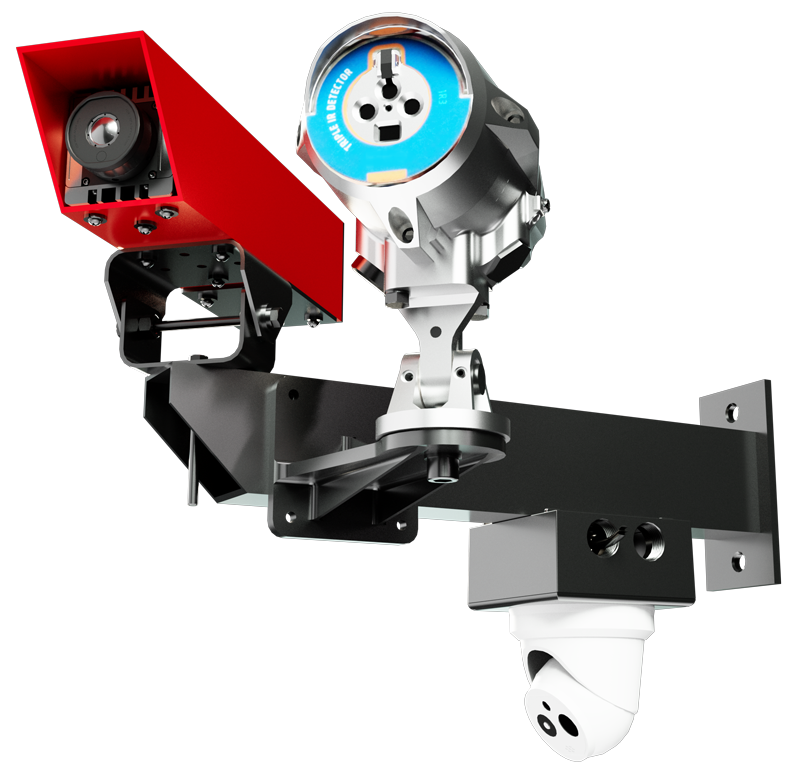

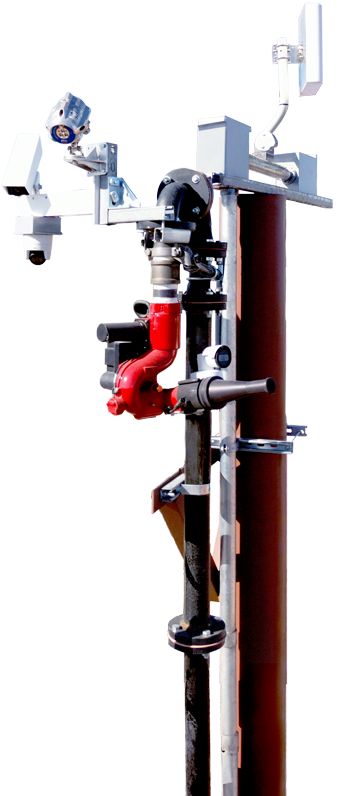

Advanced fire suppression includes automated monitoring and targeted systems — like Fire Rover — which use remote operators, smoke analytics, and thermal cameras to detect hotspots before ignition, then apply the correct suppression method in seconds.

Safety considerations matter. Not every suppression method is equally safe for people or equipment. Water is safe for humans but not for electronics. Clean agents are safe for assets but costly to deploy. Choosing the right solution requires balancing risk, compliance, and safety goals.

When Is a Fire Suppression System Required?

Many facilities don’t just benefit from suppression systems — they are required by law.

Regulatory Requirements: Agencies like NFPA (National Fire Protection Association) and OSHA (Occupational Safety and Health Administration) set minimum standards. Codes such as NFPA 13 (sprinklers) and NFPA 2001 (clean agent systems) are widely enforced.

Common Environments:

- Warehouses storing combustible materials

- Manufacturing plants with flammable processes

- Recycling facilities and waste management sites

- Data centers with sensitive electronics

High-Risk Scenarios:

- Combustible dust (wood, grain, metal dust)

- Flammable liquids and chemicals

- Lithium-ion battery storage and charging

If your facility falls into these categories, suppression systems aren’t optional — they’re essential for compliance, insurance coverage, and liability protection.

5 Common Methods of Fire Suppression

Different situations call for different tools. Here are the five most widely used fire suppression methods and their pros and cons:

1. Water-Based Sprinkler Systems

- Pros: Widely available, reliable, cost-effective

- Cons: Water damage to property and electronics, less effective on chemical or electrical fires

- Best For: Commercial buildings, offices, and general storage

2. Foam Suppression Systems

- Pros: Smothers oxygen and cools, effective for flammable liquids\

- Cons: Cleanup required, environmental concerns

- Best For: Warehouses storing fuels, recycling plants, aircraft hangars

3. Gas Suppression Systems

- Pros: Clean, no residue, effective for sensitive equipment

- Cons: High installation and maintenance cost

- Best For: Data centers, server rooms, control facilities

4. Dry Chemical Systems

- Pros: Fast, effective on multiple fire classes (A, B, C)

- Cons: Residue cleanup, corrosive to equipment

- Best For: Industrial kitchens, vehicle fleets, hazardous storage

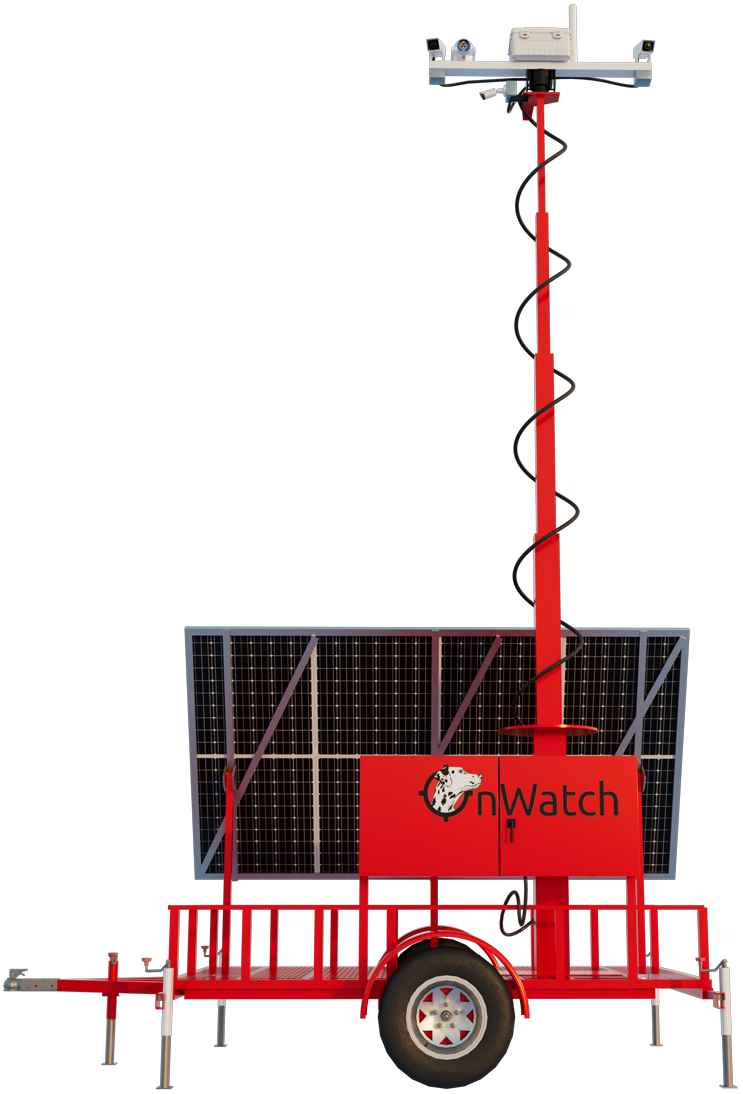

5. Mobile or Targeted Suppression Solutions

- Pros: Flexible, scalable, and can address hotspots before a full fire develops

- Cons: Requires monitoring and trained staff or automation

- Best For: Industrial facilities, recycling plants, lithium-ion battery storage

Challenges and Innovations in Fire Suppression

While traditional suppression systems are effective, they come with serious challenges:

- Re-Ignition Risks: Lithium-ion batteries and combustible dust can reignite even after suppression.

- Collateral Damage: Water, foam, and powders can damage sensitive equipment and create downtime.

- Compliance Gaps: Facilities may install systems for minimum compliance rather than best practice.

Emerging risks make these challenges more urgent:

- Lithium-ion battery fires in EV fleets, recycling centers, and warehouses

- Waste and recycling facility fires triggered by improper disposal of batteries

- New energy technologies creating unfamiliar hazards for traditional suppression methods

Innovations like Fire Rover’s remote monitoring and targeted suppression towers are designed to fill these gaps, providing real-time detection and intervention before fires escalate.

How To Choose the Right Fire Suppression Solution

There is no “one-size-fits-all” fire suppression method. Choosing the right system depends on:

- Facility Type: Offices may only need sprinklers, while recycling facilities require foam or chemical solutions.

- Specific Hazards: Lithium-ion batteries require different suppression than combustible dust or flammable liquids.

- Compliance Needs: Meeting NFPA and OSHA requirements is non-negotiable.

- Budget and ROI: While some systems have higher upfront costs, they prevent catastrophic downtime and losses.

For example:

- Data centers → clean agent gas systems

- Industrial kitchens → wet chemical suppression

- Recycling facilities → targeted foam or mobile suppression

- Battery storage sites → advanced detection and rapid-response suppression (Fire Rover)

The best system is the one that fits your risk profile while ensuring long-term safety and compliance.

Protect Your Facility With the Right Fire Suppression Strategy

Fire spreads fast — but the right plan can stop it faster. Whether you’re asking how to suppress a fire at home or evaluating advanced industrial systems, understanding the methods of extinguishing fire is critical for safety, compliance, and business continuity.

At Fire Rover, we specialize in detecting and suppressing fires before they escalate. From lithium-ion storage risks to large-scale recycling facilities, our targeted suppression systems are built for today’s toughest fire hazards.

Contact us today to learn how Fire Rover can help protect your people, property, and operations.