Fires in industrial and commercial settings can escalate in seconds, putting lives, property, and entire operations at risk. That’s why fire suppression systems are not just recommended — in many cases, they’re required by law. But understanding fire suppression system requirements can be overwhelming. Regulations vary by industry, facility type, and local jurisdiction, and what works for one environment may not be legal or effective in another.

So, when are fire suppression systems required? Where are they required? And what exactly does a fire suppression system consist of? This guide breaks it down, covering the most common codes, industry expectations, and compliance challenges businesses face. Whether you operate a data center, manufacturing plant, commercial kitchen, or high-risk industrial site, knowing the rules helps you protect your people, stay compliant, and avoid devastating losses.

The Basics of Fire Suppression Requirements

At its core, a fire suppression system is a collection of equipment designed to detect, contain, and extinguish fires quickly. While many people think of sprinklers as the default, sprinklers are just one type of suppression system — and they aren’t suitable for every environment. In fact, some facilities legally cannot rely on water because of the damage it would cause to sensitive equipment or volatile chemicals.

Regulatory Bodies and Codes

Requirements for fire suppression systems are shaped by several key organizations and standards:

- NFPA (National Fire Protection Association): Publishes dozens of codes such as NFPA 2001 (clean agent systems), NFPA 12 (carbon dioxide systems), and NFPA 17 (dry chemical systems)

- OSHA (Occupational Safety and Health Administration): Mandates safe working conditions, which often means suppression systems in hazardous workplaces

- International Fire Code (IFC): Adopted by many municipalities, outlining where suppression systems are required

- Local Fire Marshals and Authorities Having Jurisdiction (AHJs): Interpret and enforce these codes at the state and local level

Because enforcement can differ between jurisdictions, businesses must work closely with both regulators and certified fire protection professionals to confirm what’s required for their facility.

When Are Fire Suppression Systems Required?

So, when are fire suppression systems required? The answer depends on what your facility does and what hazards are present. In general, suppression is mandatory when the risk of fire is high and traditional measures (like sprinklers or extinguishers) aren’t enough.

Some common situations where suppression is legally required include:

- Data Centers and Server Rooms: Clean agent or inert gas systems are often required because water would destroy critical equipment.

- Commercial Kitchens: Wet chemical systems are mandated by code to handle grease and cooking oil fires.

- Hazardous Material Storage: Facilities storing flammable liquids, gases, or chemicals must have suppression designed for those hazards.

- Manufacturing Facilities: High-risk processes like welding, metal shredding, or woodworking typically require suppression in addition to alarms.

The takeaway: If your business involves combustible materials, sensitive equipment, or processes that generate sparks or heat, a suppression system may not just be smart — it may be non-negotiable.

Where Are Fire Suppression Systems Required?

Closely related to “when” is the question: where are fire suppression systems required? Regulatory codes outline specific facility types and environments, including:

- Warehouses and Distribution Centers (especially those with flammable inventory)

- Industrial Plants (metal processing, chemical production, recycling)

- Commercial Kitchens and Restaurants

- Laboratories and Research Facilities

- Marine Vessels (ships, offshore rigs, cargo holds)

- Power Generation Plants and Utilities

- Waste and Recycling Facilities (where combustible material and lithium-ion batteries are growing fire risks)

The exact system type will vary, but if your facility falls into one of these categories, a suppression system is almost always required by code.

Core Requirements for All Fire Suppression Systems

What Does a Fire Suppression System Consist Of?

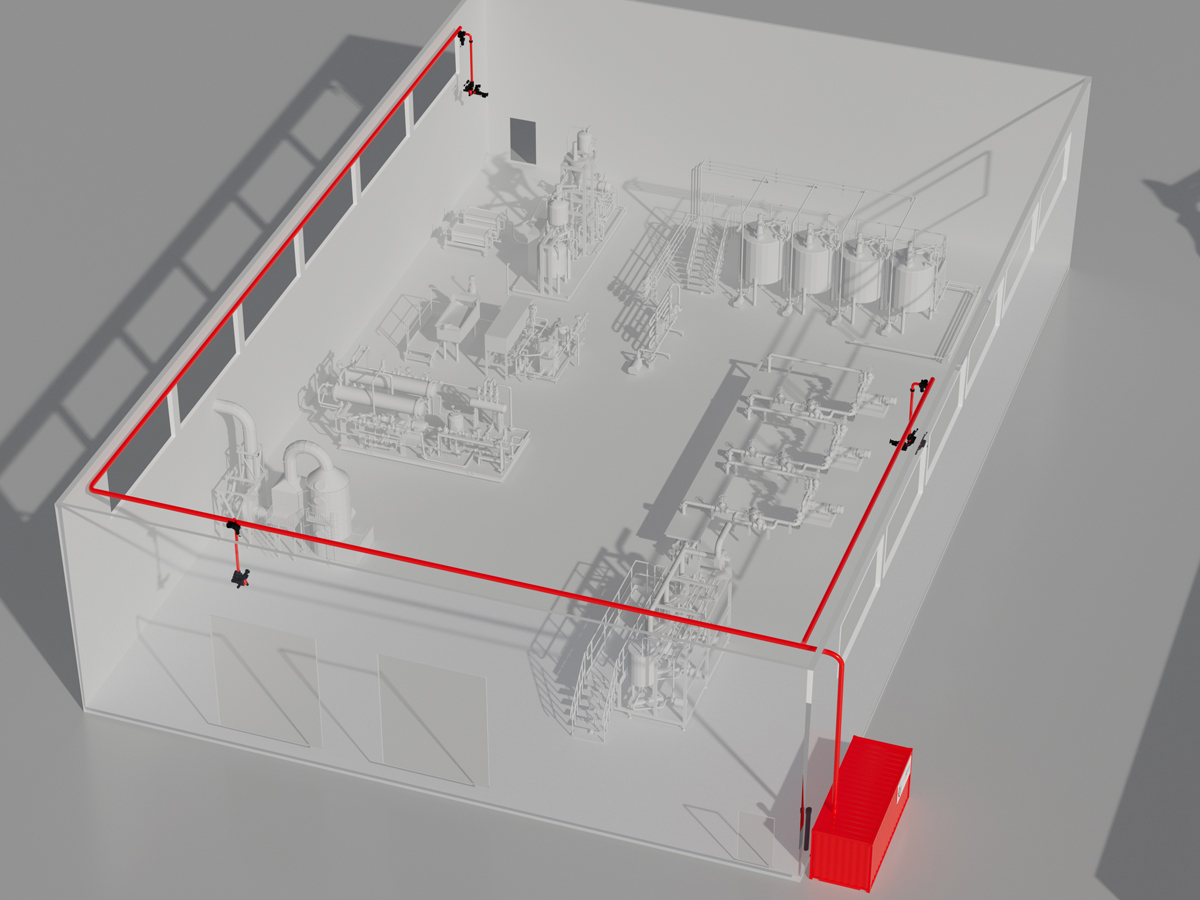

No matter the environment or agent type, most systems share four core components:

- Agent Storage: Tanks or cylinders that hold the suppression medium (water, foam, gas, or chemical)

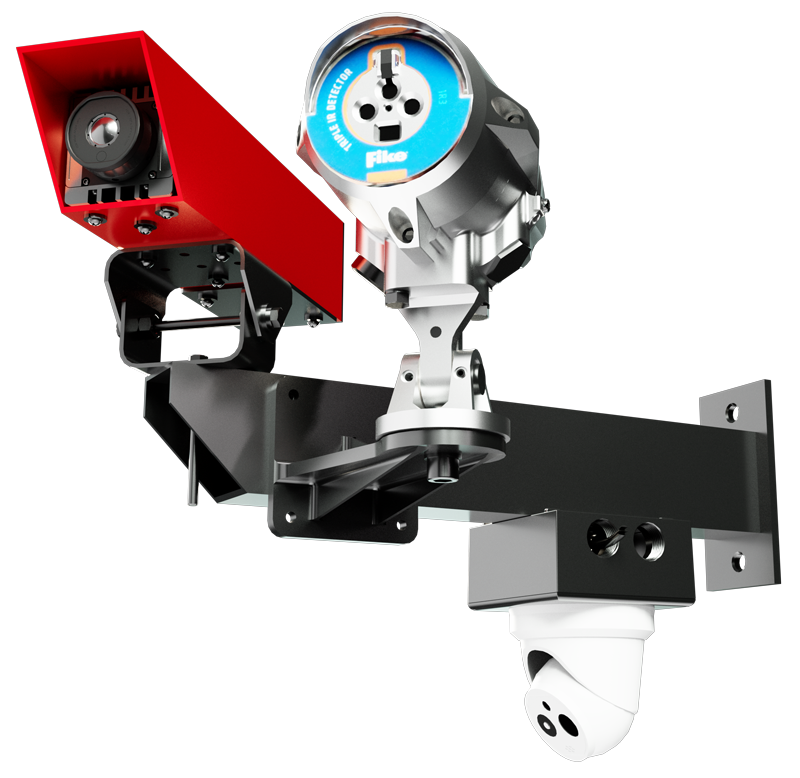

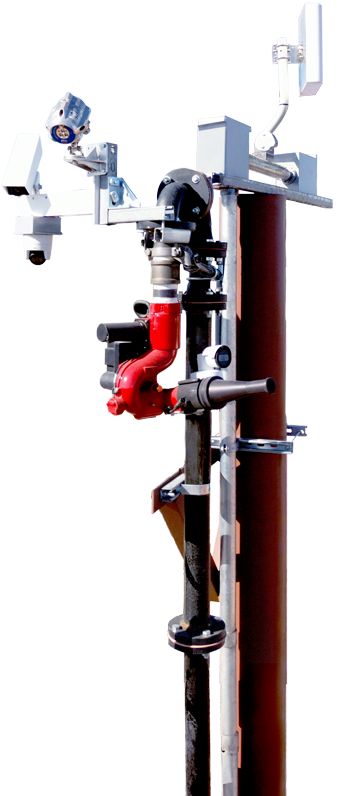

- Detection System: Heat, smoke, or flame detectors that identify a fire event

- Distribution Network: Piping and nozzles that deliver the agent to the fire

- Control Panel: The “brain” of the system that activates suppression automatically or by manual pull

Together, these elements form an end-to-end system designed to catch fires early and suppress them before they spread.

Performance Standards

Codes also dictate how systems must perform:

- Discharge Time: Agents must release quickly enough to suppress fires in their early stages.

- Coverage Area: No blind spots — every part of the hazard area must be protected.

- Agent Type: Must match the hazard (e.g., wet chemicals for grease, inert gas for electronics).

Inspection, Testing, and Maintenance

Even the best system is useless without proper upkeep. NFPA standards typically require:

- Annual inspections by certified technicians

- Regular discharge tests and alarm integration checks

- Documentation of all maintenance and tests

- Proper labels, system diagrams, and clear instructions posted at the site

Failure to maintain compliance can result in fines — or worse, a system that fails when you need it most.

Industry-Specific Fire System Requirements

While the core rules apply broadly, industries have unique needs:

- Data Centers and Server Rooms: Require non-water systems (clean agents or inert gases) to prevent downtime and data loss. Even a small fire can cost millions in lost business.

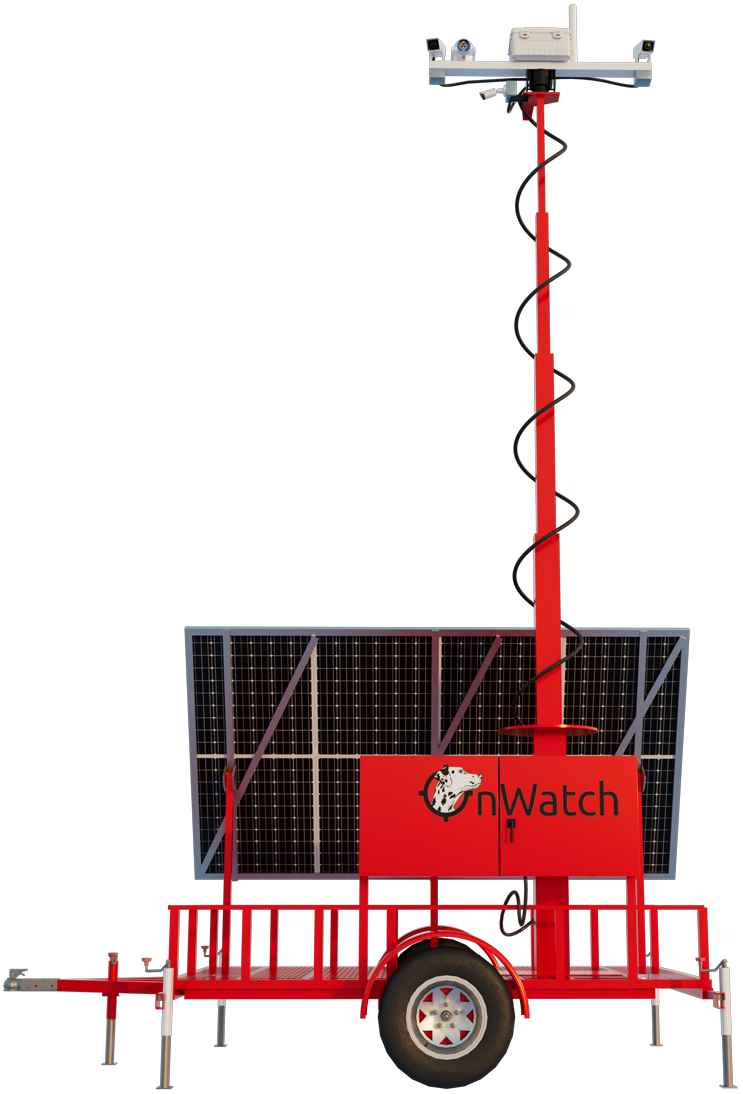

- Industrial and Manufacturing: Sparks, flammable dust, and hazardous processes mean suppression must be robust and tailored. In scrap metal, recycling, or wood processing, systems like Fire Rover provide outdoor coverage where fixed systems can’t.

- Commercial Kitchens: NFPA 17A requires wet chemical systems above fryers, grills, and hoods. These are legally mandated because grease fires spread too quickly for extinguishers alone.

Each of these industries faces both regulatory requirements and insurance pressures, making suppression systems a critical part of operations.

Compliance Challenges Businesses Face

Meeting fire suppression system requirements isn’t always straightforward. Businesses often encounter challenges such as:

- Maintenance Lapses: Systems that aren’t inspected or tested regularly may fail during an incident.

- Outdated Systems: Older facilities may still have halon systems or insufficient coverage.

- Misconceptions: Some assume that “minimum compliance” is enough — but best practice often goes beyond the legal baseline.

- Local Variations: Two plants in different states may face different interpretations of the same NFPA code.

These challenges underline the importance of proactive fire protection planning — not just checking boxes for compliance, but designing a system that truly protects people and operations.

Protect Your Facility With Confidence

At the end of the day, compliance isn’t just about avoiding fines — it’s about safeguarding lives, property, and business continuity. By understanding fire suppression system requirements and tailoring your approach to your specific environment, you can prevent catastrophic losses and give your team peace of mind.

Traditional systems like sprinklers, foams, and clean agents have their place — but they can’t cover every risk. That’s where Fire Rover comes in, providing early detection, human verification, and targeted suppression for high-risk industries like waste, recycling, and scrap metal.

Ready to ensure your facility meets — and exceeds — fire suppression system requirements? Contact Fire Rover today to learn how we can protect your operation.