When it comes to protecting people, property, and operations, fire suppression systems are a critical line of defense. Fires don’t just destroy assets — they disrupt business continuity, endanger employees, and create compliance and liability issues. According to the National Fire Protection Association (NFPA), U.S. businesses experience tens of thousands of workplace fires every year, causing billions in annual losses.

That’s why understanding the different types of fire suppression systems is so important. From traditional water-based sprinklers to advanced agent-based solutions and innovative systems like Fire Rover, there’s no one-size-fits-all answer. Each industry faces unique risks, and choosing the right fire suppression system type can mean the difference between a small incident and catastrophic loss.

In this guide, we’ll cover the most common fire suppression system examples, how they work, their strengths and limitations, and which environments they’re best suited for.

The Importance of Fire Suppression Systems

The cost of a fire extends far beyond property damage. Businesses that experience even a small blaze often face weeks or months of downtime, not to mention legal and insurance challenges. OSHA and NFPA standards also require certain suppression systems depending on the industry, making compliance just as critical as safety.

Some of the biggest risks businesses face without proper suppression include:

- Operational Downtime: Fires can shut down production lines, warehouses, or entire facilities.

- Asset Loss: From equipment and inventory to data and intellectual property.

- Safety Concerns: Employees and first responders face higher risks in facilities without adequate suppression.

- Regulatory Penalties: Non-compliance with fire codes and insurance requirements can result in heavy fines.

NFPA standards like NFPA 13 (sprinkler systems), NFPA 2001 (clean agent systems), and NFPA 17/17A (dry and wet chemical systems) provide the benchmarks industries are expected to follow. Falling short doesn’t just raise risk — it exposes companies to legal and financial liability.

The right suppression system not only reduces these risks but also demonstrates a proactive commitment to safety — something insurers, partners, and customers increasingly expect.

7 Types of Fire Suppression Systems

Each fire suppression system type has a specific role to play. Below, we break down the most common options, along with their pros, cons, and best-fit applications.

1. Water-Based Systems

Overview:

Water is the most widely used suppression medium, delivered via sprinklers, deluge systems, or water mist systems.

Best For:

- Commercial offices

- Warehouses

- Retail spaces

Strengths:

- Proven effectiveness against Class A fires (ordinary combustibles)

- Relatively low installation and maintenance costs

- Widely available replacement parts and service providers

Weaknesses:

- Can cause extensive water damage

- Less effective on electrical fires or flammable liquid fires

- Not ideal for facilities with sensitive equipment

Cost Considerations:

Generally among the most affordable systems to install and maintain, making them a staple for code compliance in most commercial buildings.

Example:

A retail store’s sprinkler system can prevent a small stockroom fire from spreading to the sales floor, saving millions in merchandise and avoiding store closure.

2. Clean Agent Systems

Overview:

These systems release chemical gases (like FM-200 or Novec 1230) that extinguish fires by removing heat or disrupting the chemical reaction.

Best For:

- Data centers

- Server rooms

- Museums and archives

Strengths:

- No residue — protects electronics, documents, and artifacts

- Fast-acting

- Safe for occupied spaces

Weaknesses:

- Higher upfront cost

- Requires sealed environments to work effectively

Cost Considerations:

Installation costs are higher than water systems, but they often reduce long-term risk of damage to sensitive assets.

Example:

A clean agent system in a server room prevents fire damage while avoiding the catastrophic water damage a sprinkler system would cause.

3. Inert Gas Systems (CO₂ and Others)

Overview:

CO₂ or other inert gases displace oxygen to suffocate the fire.

Best For:

- Industrial facilities

- Power generation plants

- Marine applications

Strengths:

- Effective on Class B and Class C fires

- Leaves no residue or cleanup

Weaknesses:

- Dangerous for occupied areas (oxygen displacement hazard)

- Complex design and installation

Cost Considerations:

Often high in both installation and monitoring, but effective in environments where traditional suppression is too risky.

Example:

Ship engine rooms often rely on CO₂ systems because water or foam suppression could damage critical equipment.

4. Foam Systems

Overview:

Foam systems create a blanket over flammable liquids, cutting off oxygen and preventing re-ignition.

Best For:

- Aircraft hangars

- Chemical plants

- Oil and gas facilities

Strengths:

- Extremely effective against Class B fires (flammable liquids)

- Can cool and suppress simultaneously

Weaknesses:

- Requires special storage tanks and distribution equipment

- Ongoing maintenance can be costly

Cost Considerations:

Higher upfront investment due to specialized infrastructure but essential in industries with liquid fuel hazards.

Example:

Foam suppression in an aircraft hangar can contain jet fuel fires before they spread across the floor, saving lives and equipment.

5. Dry Chemical Systems

Overview:

Dry chemicals (like monoammonium phosphate) disrupt the chemical reaction of fire. Often used in portable extinguishers and fixed systems.

Best For:

- Industrial manufacturing

- Paint booths

- Storage facilities

Strengths:

- Inexpensive and widely available

- Effective against Class A, B, and C fires

Weaknesses:

- Residue cleanup can be extensive

- Can damage electronics and sensitive equipment

Cost Considerations:

Budget-friendly but with higher post-discharge cleanup costs.

Example:

A fixed dry chemical system in a paint booth ensures a solvent-based fire doesn’t spread, keeping the facility operational.

6. Wet Chemical Systems

Overview:

Specially formulated wet chemical agents (often potassium-based) designed for kitchen fires.

Best For:

- Commercial kitchens

- Restaurants

- Food processing facilities

Strengths:

- Cools and reacts with oils to form a soap-like layer that prevents re-ignition

- Required by code for kitchens with fryers and grills

Weaknesses:

- Limited application outside of food-service environments

Cost Considerations:

Moderately priced and required by NFPA 17A in kitchens, making them a non-negotiable investment.

Example:

A restaurant fryer fire suppressed by a wet chemical hood system prevents loss of business and ensures compliance with health and safety codes.

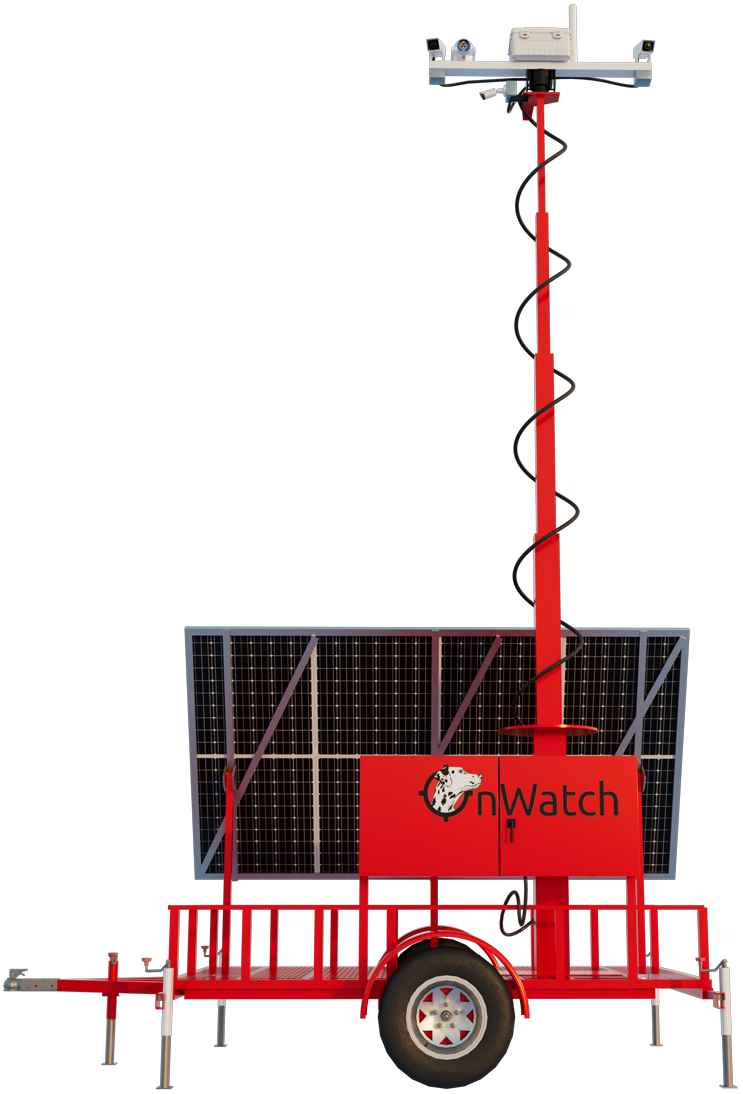

7. Fire Rover Systems

Overview:

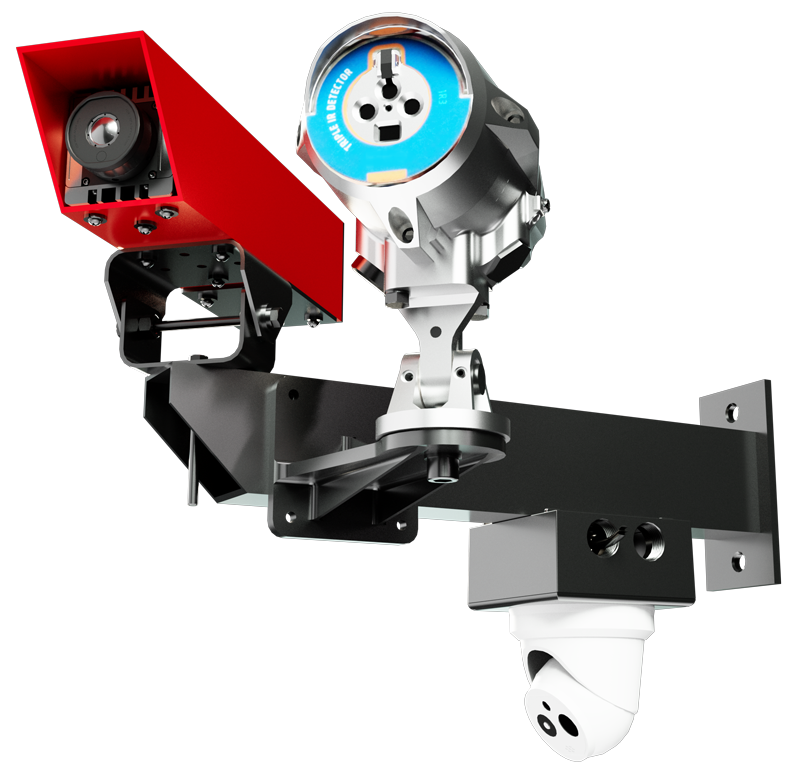

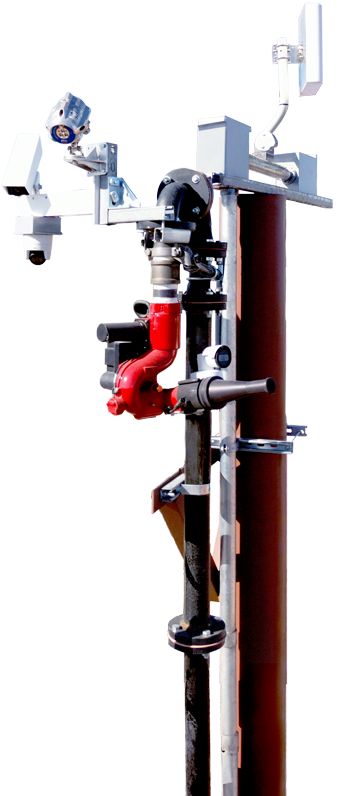

Unlike traditional fixed systems, Fire Rover provides a mobile, human-verified fire detection and suppression solution. It combines thermal imaging, AI-driven monitoring, and remote operators to detect hotspots early and deploy targeted suppression.

Best For:

- Waste and recycling facilities

- Landfills

- Wood processing and hot works environments

- Scrap metal operations

Strengths:

- Detects and responds before flames spread

- Remote monitoring with human verification reduces false alarms

- Targeted suppression avoids flooding entire areas

- Works outdoors and in environments where traditional systems fail

Weaknesses:

Tailored primarily to high-risk industries rather than general use

Cost Considerations:

Custom-designed for high-risk operations. Costs vary by facility but are offset by avoiding catastrophic losses.

Example:

A recycling center fire is detected at the smoldering stage by Fire Rover, suppressed before it spreads to surrounding piles — preventing millions in damages and lost revenue.

How to Choose the Right Fire Suppression System

With so many fire suppression types available, choosing the right one depends on your specific risks, facility layout, and compliance requirements. Factors to consider include:

- Primary Hazards: A data center’s primary risk is electronics, requiring clean agents. A scrap yard faces flammable debris — better suited to Fire Rover.

- Environment: Enclosed rooms may benefit from gas systems, while large warehouses often need sprinklers. Outdoor or mixed-use yards need specialized solutions.

- Compliance: Local fire marshals and insurance carriers may mandate specific systems. NFPA codes guide the design for nearly every environment.

- Downtime Costs: Beyond installation, consider how long your business can afford to be offline after an incident. Some systems allow faster recovery than others.

- Budget vs. Risk Tolerance: A higher upfront investment in advanced suppression may save exponentially more in avoided losses.

In some cases, the right solution may be a hybrid — sprinklers for general coverage, clean agents for sensitive rooms, and Fire Rover for outdoor combustible storage.

Protect Your Business With the Right Fire Suppression Strategy

Every fire suppression system has strengths, but not every system works everywhere. Understanding the different fire suppression system types ensures you can match the right technology to your risks.

Fire Rover is designed for the toughest environments — waste, recycling, landfills, and other high-risk industries — where traditional systems often fall short. With early detection, human verification, and targeted suppression, we help businesses stop fires before they spread.

Ready to protect your facility? Contact Fire Rover today to learn how our solutions can be tailored to your operation.